For example, the thermal responsive hydrogel is used to realize programmable deformation of the soft sheet by patterning chemically distinct, fiber-like regions that exhibit different shrinkage and modulus under the external stimulus ( Wu et al., 2013). In consideration of the simplicity of operation and the applicability, the thermal responsive structure is one of the most widely used 4D printed structures. In view of the characteristics of shape morphing, applications of the 4D printed structure can be extended to diverse areas such as soft robotics ( Kim et al., 2018, 2019 Kotikian et al., 2018 Yang et al., 2018 Zhu et al., 2018), origami ( Ge et al., 2014 Liu et al., 2018 Teoh et al., 2018), biomedical device ( Morrison et al., 2015 Gao et al., 2016 Zarek et al., 2017 Lin et al., 2020), tissue engineering ( Villar et al., 2013 Li et al., 2016 Gill et al., 2018), and metamaterials ( Xin et al., 2020), etc.

4D printing enables the printed structure to change its shape, property, and functionality under the external stimuli such as temperature ( Ambulo et al., 2017 Ding et al., 2017 Kotikian et al., 2018), magnetic field ( Kim et al., 2018, 2019 Zhu et al., 2018), light ( Kuksenok and Balazs, 2016 Leist and Zhou, 2016 Yang et al., 2017), and pH ( Nadgorny et al., 2016), etc. By combining with smart materials, 3D printing is further extended to 4D printing with the addition of time-dependent response to external stimuli. Based on the 4D printed pre-strained bilayer structure, an energy-free gripper is fabricated and a fully soft crawler is printed to achieve a high running speed.ģD printing is a widely used additive manufacturing technology that can embody objects from digital 3D models rapidly and inexpensively in contrast to traditional manufacturing techniques. Through experiments and the finite element analysis, it is demonstrated that the aspect ratio has little effect on the deformation of the bilayer structure, whereas the pre-strain plays a key role in the deformation and also greatly accelerates the actuation of the bilayer structure. A bilayer structure with one pre-strained layer and the other non-pre-strained layer is integrally printed.

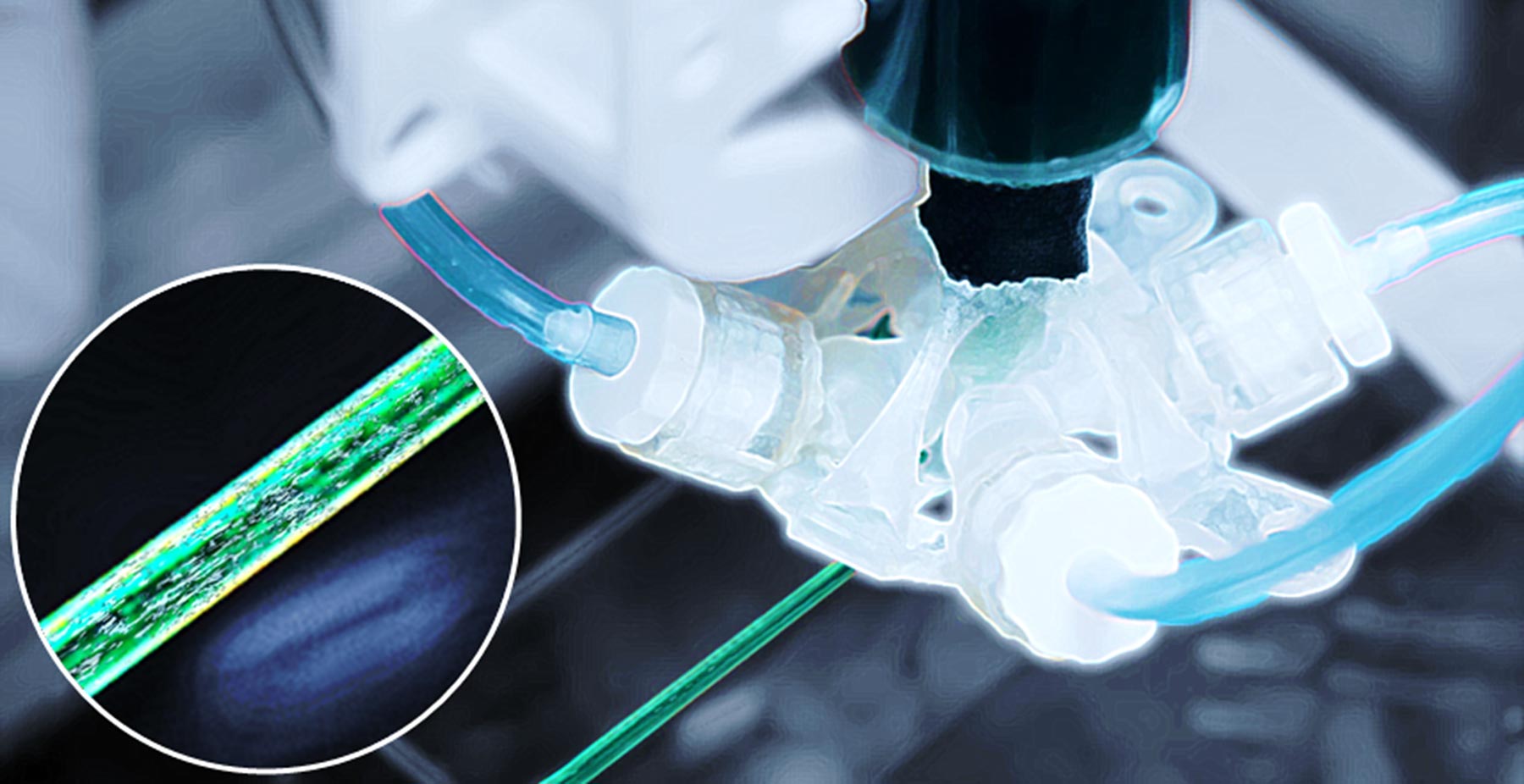

A 4D printing platform that can apply strain during the printing process is constructed to fabricate the pre-strained structures under the aid of in-situ tensile of the printing base. In the current work, a pre-strained strategy is proposed to accelerate the actuation of thermal responsive structures.

However, the slow actuation of the thermal responsive structures impedes the applications like soft robotics. Among the existing 4D printed structures, thermal responsive structures are widely used for their easy operation. It enables the 3D printed structure to change the shape, property, or functionality under external stimuli such as temperature, magnetic field, and light, etc. State Key Laboratory for Turbulence and Complex Systems, Department of Mechanics and Engineering Science, BIC-ESAT, College of Engineering, Peking University, Beijing, Chinaįour-dimensional (4D) printing is an emerging technology by adding the dimension of time-dependent reconfiguration into 3D printing.Yu Zou Zhongyi Huang Xiying Li Pengyu Lv *

0 kommentar(er)

0 kommentar(er)